Next week I will be presenting our latest paper called “CrossFill: Foam Structures with Graded Density for Continuous Material Extrusion” at the Symposium on Solid and Physical Modeling which is part of the International Geometry Summit.

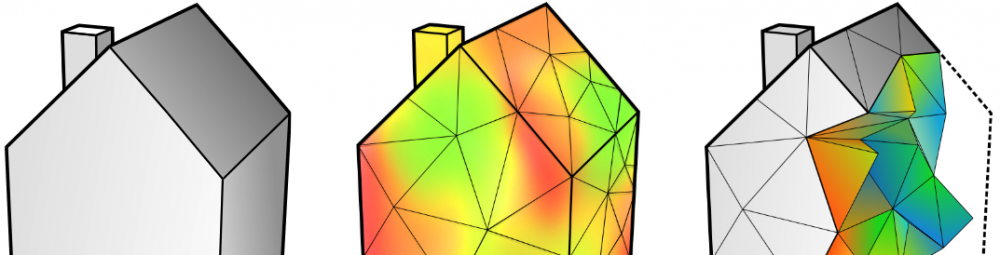

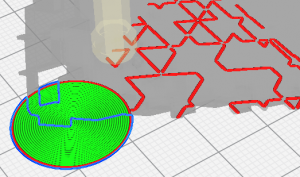

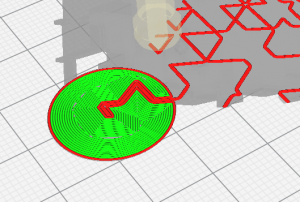

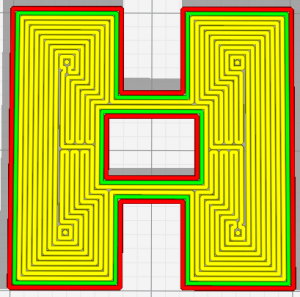

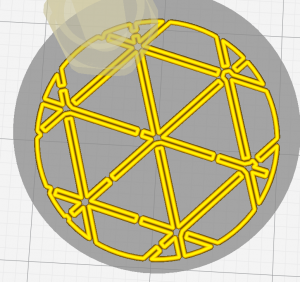

We present an infill structure which satisfies a user-specified density field in order to generate infill with densities which gradually change throughout the object.

The infill pattern is very compliant and when you print these infills using a flexible filament such as TPU, the structures behave like a foam.

[youtube]https://youtu.be/lcLcsprxIHw[/youtube]

There are also some options in Cura to ensure that the infill structure has an almost fully connected channel of air inside – just like gyroid infill does.

However, in my latest implementation I had to remove these features, because the expanded functionality of following a user-specified density distribution couldn’t support the idea of keeping connected air channels inside.

Homogeneous CrossFill is already incorporated in Cura, but some of the features I present here are not yet incorporated.

The infill pattern has become the industry standard for printing with TPU by now.

The paper can be accessed for free for a limited amount of time via the this link.

Otherwise you can access the pre-print here.