Process Planning for Fused Deposition Modeling: Beyond the Boundary of a Mesh

PhD candidate: Tim Kuipers

Supervisory team: Jun Wu (TU Delft), Peter Brier (Ultimaker), Charlie Wang (TU Delft)

Project start: Sept 2017

- A collaboration between Ultimaker and Delft University of Technology

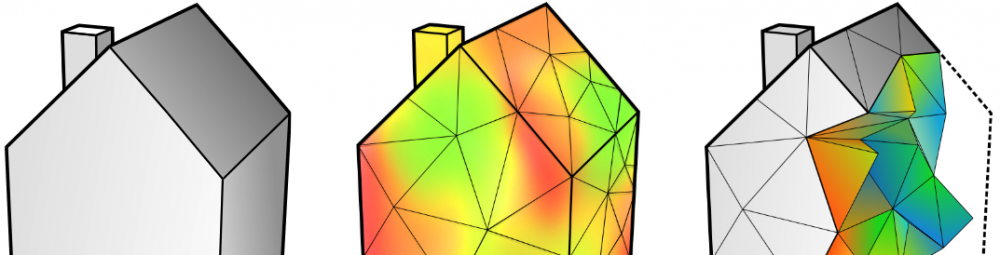

In this project we investigate innovative and efficient techniques for opening new capabilities in Fused Deposition Modeling (FDM), a commonly used additive manufacturing (a.k.a. 3D printing) technology. Our vision is that future products could be 3D printed in full-color, with high fidelity and structural integrity, while minimizing the required print time. This requires to move beyond the boundary of a mesh – besides mesh boundary location information the input model requires three-dimensionally defined volumetric information or additional mesh boundary properties.

To fulfill this vision we focus on process planning – a stage in the product development pipeline situated between designing a model and printing it. Examples of applied research questions include:

How can infill structures be optimized to provide support and strength only where needed?

How can we generate infill structures to satisfy certain volumetric properties?

How can support structures be generated with the least amount of material which only touch the model where needed?

How can process planning use textured objects to manufacture products with full-color or monochrome appearance?

What adaptive slicing techniques can we apply to only have a high resolution layer height where it’s needed?

While the methodology-to-be-developed is applicable (possibly by extension) for 3D printing in general, we will focus on methods which are directly applicable to FDM systems which are developed by Ultimaker or might be developed by Ultimaker in the future. In particular, we consider methods applicable to multi-extrusion plastic jet printers without hardware modifications.

Aiming at the highest impact in academia and industry, we will publish the research outcome in scientific journals such as Computer-Aided Design. Meanwhile, the envisioned algorithms will be developed in a software environment compatible with the Cura process planning software package.

The successful implementation of this project relies on support from TU Delft and Ultimaker. The Advanced Manufacturing group at TU Delft, has been continuously contributing scientific knowledge in design for manufacturing, including recent works on surface quality and infill strength optimization. Ultimaker is one of the biggest players in the FDM market. The slicing software, Cura, co-developed by the PhD candidate has been widely used in the 3D printing community.